Module Spiral Bevel Gears to Gleason Standard

Enquire about Module Spiral Bevel Gears to Gleason Standard

- Description

- Range of Sizes

- Alt. Shaft Fixing

- Free Drive Design

- Reworking Service

- Plating Service

- Manufacturing

- Tips

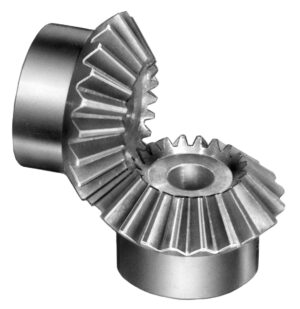

Description

1.5, 2.0, 2.5, 3.0 4.0, & 5.0, Mod with 1:1 & 2:1 Ratios Pilot Bore

This stock range of Pilot Bore Metric Module Pitch Spiral Tooth are produced in accordance to the Gleason Std. and are available in six Module pitch sizes from 1.5 to 5.0 Mod in two ratio sizes and four tooth sizes in the 1:1 ratio range. They are design for general purpose application within the power transmission drive industry to transmit motion through concurrent axles with a higher loading capacity than the Straight Tooth form type.

As they are produced from C43 carbon Steel hence they are suitable for Flame Hardening.

Range of Sizes

| Module Pitch Size | Ratio 1-1 No of Teeth 16T-16T | Ratio 1-1 No of Teeth 20T-20T | Ratio 1-1 No of Teeth 25T-25T | Ratio 1-1 No of Teeth 30T-30T | Ratio 2-1 No of Teeth 16T-32T |

|---|---|---|---|---|---|

| 1.5Mod | 16T-16T | 20T-20T | 25T-25T | 30T-30T | 16T-32T |

| 2.0Mod | 16T-16T | 20T-20T | 25T-25T | 30T-30T | 16T-32T |

| 2.5Mod | 16T-16T | 20T-20T | 25T-25T | 30T-30T | |

| 3.0Mod | 16T-16T | 20T-20T | 25T-25T | 30T-30T | 16T-32T |

| 4.0Mod | 16T-16T | 20T-20T | 25T-25T | 30T-30T | 16T-32T |

| 5.0Mod | 16T-16T | 20T-20T | 25T-25T | 30T-30T | 16T-32T |

Material C43 UNI 7847 (Suitable for Flame Hardening)

Alt. Shaft Fixing

As an alternative to either Boring & Keywaying a pilot bore gear. Why not take a look at the range of Locking Bushes we now offer, as they eliminate the need for fixing via a Keyway-Key thereby providing the added benefit of a uniform distribution of the drive load over the entire diameter of the bush.

Free Drive Design

Free Drive Selection Service

A Free Design selection service is available for this product for full details and application requirements please follow this link.

Reworking Service

To compliment the Stock range of Products the company offers an in house comprehensive reworking service to modify any stock Gear to suit your individual requirements.

Plating Service

A Full range of add on Plating Finishes is available :-

- Zinc (Clear & Yellow)

- Nickel

- Chemically Black Phosphate

- Hard Anodising for Aluminium Products!

Manufacturing

The company also provides a Manufacturing Service that caters for :-

- Any requirement outside it’s stock ranges.

- Customers own drawing requirement.

- Or when a stock pulley is not suitable.

Tips

Due to un-even wear we strongly recommend that Bevel Gears are always supplied and replaced as a mating pair.